Cost Saving Solutions

Domeny Tool & Stamping Company has a long-demonstrated history of concurrent engineering and metallurgy support for our customers across a wide range of industries. Below you will find just a sampling of the cost savings we have been able to provide our customers for over 60 years.

1959 – 1965

Industry: Automotive – all major OEMs

Cost savings: 60% overall cost reduction

Concurrent engineering and metallurgy support to replace drawn brass and bronze stampings for automotive water pump seals with more cost-effective drawn stainless stampings.

1965 – 1975

Industry: Department of Defense

Cost savings: 80% overall cost reduction

Metallurgy support to redesign bomb fuse components from Beryllium copper to more economical and safer USAmet (stainless steel superalloy)

1970 – 1990

Industry: Memorial Lamps

Concurrent engineering support to redesign and produce tooling for grave side memorial lamps to be manufactured in aluminum, thus improving the longevity of product.

1975 – 1985

Industry: Oil Refineries and Pipeline Industries

Cost savings: 90% overall cost reduction

Concurrent engineering and metallurgy support to redesign machined Hastelloy bellows seals to be manufactured more economically via drawn Hastelloy stampings.

1980 – 1990

Industry: Construction & Building Supplies

Cost savings: Significant cost reduction and increased safety performance

Concurrent engineering and metallurgy support by redesigning window clip components for high rise buildings. The manufacturing process was changed to replace heat treated/plated steel with pre-tempered stainless steel resulting in improved safety, lower failure rate, and maximum cost efficiency.

Industry: Mining/Safety Equipment

Concurrent engineering and metallurgy support to help design and manufacture re-breather end caps for the breathing apparatus used in mining activities.

Industry: Off Road and Farm Equipment

Cost Reduction: 90% overall cost reduction

Concurrent engineering to redesign machined components into more economical drawn metal stampings for the largest commercial producer of farm equipment in the US.

1980 – 2010

Industry: Industrial Safety Supply

Concurrent engineering and die design support to produce stampings, included in numerous safety products sold by a major safety equipment supplier.

1990 – 2000

Industry: Automotive – all major OEMs

Cost savings: 80% overall cost reduction

Concurrent engineering and metallurgy support to redesign a machined door insert to a more economical stamped insert using D shaped wire.

2000 – 2010

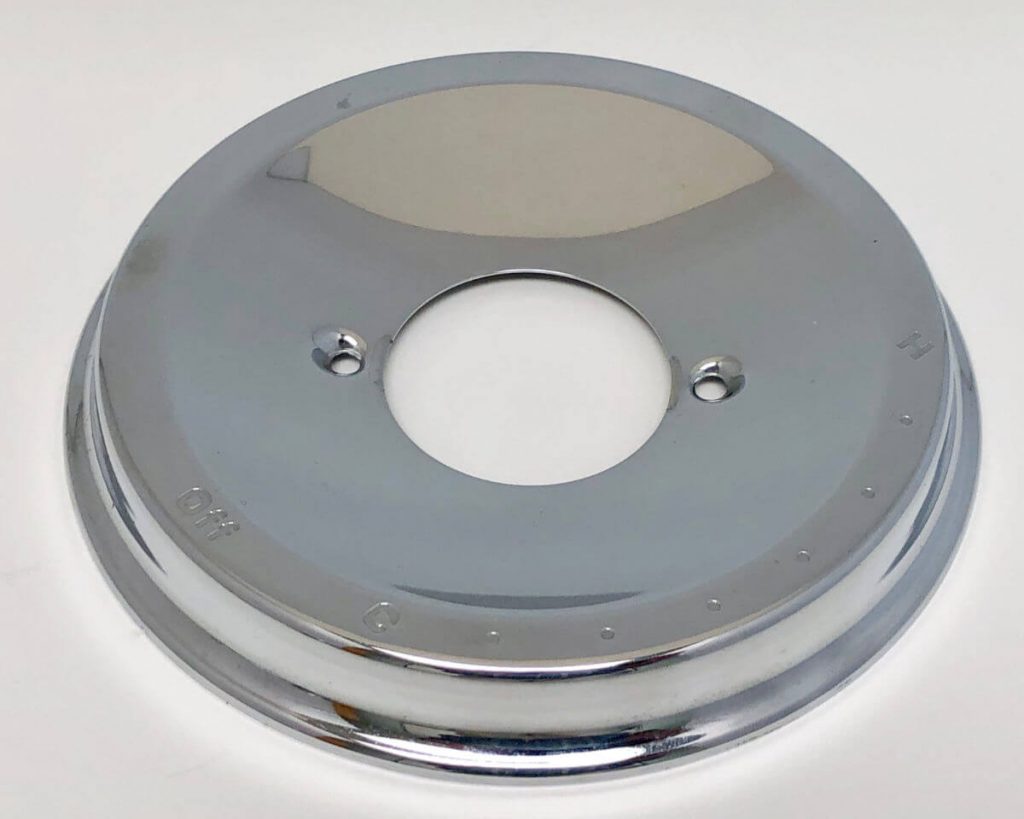

Industry: Home Improvement/Plumbing Supply

Cost savings: 70% overall cost reduction

Concurrent engineering and metallurgy support to redesign a die cast and plated shower escutcheon to a more economical drawn and plated stamping.

1990 – Ongoing

Industry: Electrical/Power

Cost savings: 70% overall cost reduction

Concurrent engineering and metallurgy support to redesign power fuse caps from 90/10 bronze stampings to more cost-effective 300 series stainless steel stampings.

2000 – Ongoing

Industry: Automotive – Global

Concurrent engineering support to redesign, prototype and produce tooling for multiple drawn stampings supplied to a top Fortune 100 Global Automotive Company. Production volumes increasing.

2010 – Ongoing

Industry: Semiconductor/Health & Medicine/Clean Room

Concurrent engineering, metallurgy support, and product design support for three weight classes of a pre-tempered, drawn, stainless steel casters. These casters are the only passive shock absorbing casters on the world market. Production volumes increasing. AtlasCasters.com

2020 – Ongoing

Industry: Health and Medical

Cost Savings: 50% cost reduction and improved overall part functionality Concurrent engineering and metallurgy support to manufacture a specialized stainless-steel stamping, redesigned from a plated stamping, for ventilator construction used during the COVID-19 Pandemic. Production ongoing.